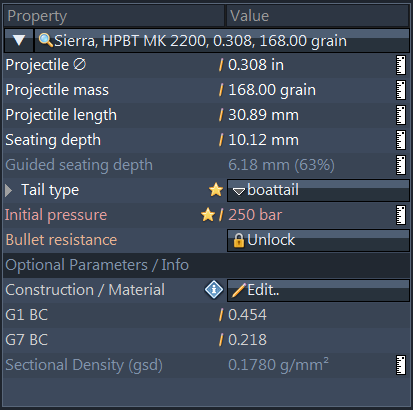

Projectile Window

The projectile window has the following fields:

The projectile window has the following fields:

All measurements in the original database where either submitted by the respective manufacturer or measured by contributing hand loaders. Projectiles of the same brand and/or model can and will have different geometries (depending on weight)

- Projectile Selection (first dropdown)

By selecting a projectile from the database, all values will be set to standard values for the given bullet.

- Projectile Diameter

The (ideally self-measured) average diameter for the bullet on its widest part

- Projectile Mass

The average weight of the bullet (best results, if measured by the hand loader)

- Projectile Length

The average length of the bullet please take your own measurements!

- Seating Depth

The total seating depth of the bullet into the case - that is the distance of the bullets tail to the mouth of the case.

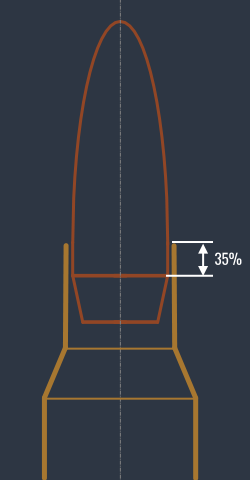

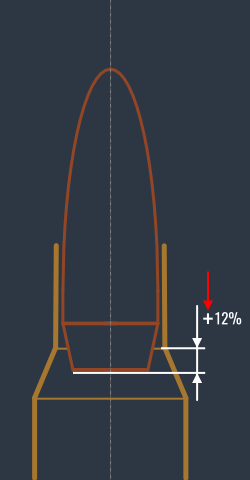

- Guided Seating Depth

The “Guided Seating Depth” is the contact length of the cylindrical projectile part and is therefore identical to the seating depth for flat-base and hollow-base projectiles.

The “Guided Seating Depth” is the contact length of the cylindrical projectile part and is therefore identical to the seating depth for flat-base and hollow-base projectiles.

For boattail projectiles additionally the percentage by which the projectile base is seated in the case mouth is shown in parentheses in relation to the case mouth length. A leading “+“ indicates that the bullet base extends into the case shoulder.

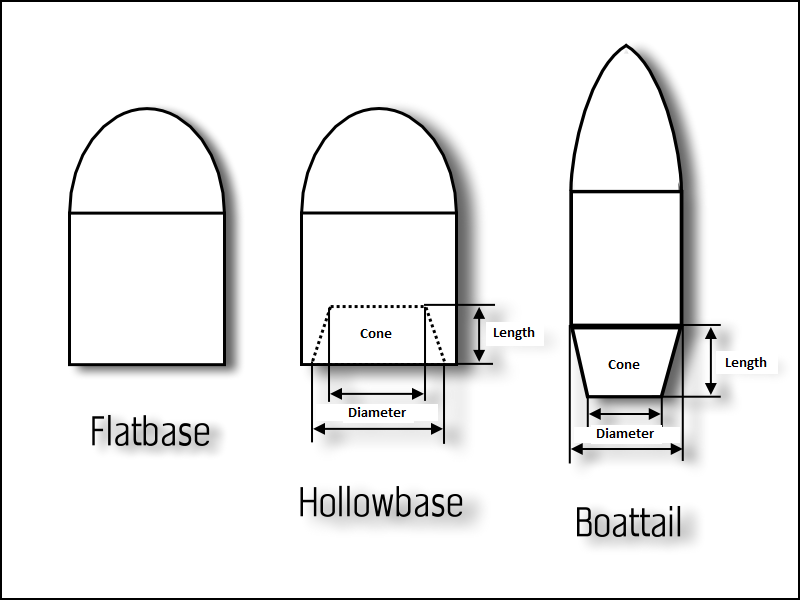

- Tail Type

GRT recognizes different tail configurations/features for bullets (this will influence the available combustion volume in some cases): “flatbase” (flat tail / base of the bullet - not influencing cartridge combustion volume), “hollowbase” (Tail with an cone shaped insert (cavity) into the bullet's tail (similar to open lead core bullets) - this will increase the available cartridge combustion volume inside the case. Finally “boattail” (a bullet with a prolonged cone tail, with decreasing diameter. - this will decrease the available cartridge combustion volume inside the case. For accurate simulation results with bullets featuring hollowbase or boattail configurations, the following parameters are essential:

GRT recognizes different tail configurations/features for bullets (this will influence the available combustion volume in some cases): “flatbase” (flat tail / base of the bullet - not influencing cartridge combustion volume), “hollowbase” (Tail with an cone shaped insert (cavity) into the bullet's tail (similar to open lead core bullets) - this will increase the available cartridge combustion volume inside the case. Finally “boattail” (a bullet with a prolonged cone tail, with decreasing diameter. - this will decrease the available cartridge combustion volume inside the case. For accurate simulation results with bullets featuring hollowbase or boattail configurations, the following parameters are essential:

- Cone Length

The lenght of the cone or depth of the cavity - Cone Diameter A & B

If boattail this is the diameter, definig the begin or the end of the cone. If hollowbase it is the diameter of the surface marking the begin or end of the cavity. Entering larger or smaller value as A or B is to the discretion of the hand loader, as GRT will calculate the appropriate cone or cavity automatically.

- Initial Pressure

The initial gas pressure (IP) is used to adjust the internal ballistic start parameters. Primary parameters are the pressure at which the bullet should start to move, the press-in pressure in the barrel grooves, pull-out resistance, primer type, powder variations and other tolerances. If you have projectile velocity and/or gas pressure measurements, you can use it to adjust the simulation to the real world. Note, however, that any adjustment only refers to the weapon used and the current load.

| Pistol-/Revolver Ammunition | |

|---|---|

| Standard Jacketet Bullets | 80-150 bar |

| Lead Bullets (standard) | 50-80 bar |

| Lead Bullets (soft) | 20-50 bar |

| Rifle Caliber | |

| Standard Jacketet Bullets | 250 bar |

| Lead Bullets (soft) | 20-80 bar |

| Lead Bullets (standard to brittle) | 80-150 bar |

| Copper/-Brass (Solid), Value depends on construction & material used! | 250-750 bar |

| Copper/-Brass (Solid), bullets with a bullet body diameter equal to the lands diameter (“BORE RIDER”) and NARROW driving bands. NOTE: Projectiles with grooved rings as relief grooves are NOT such projectiles! | 50-150 bar |

| Copper/-Brass (Solid), bullets with a bullet body diameter equal to the lands diameter (“BORE RIDER”) and WIDE driving bands. NOTE: Projectiles with grooved rings as relief grooves are NOT such projectiles! | 100-250 bar |

| Slugs/Shotgun Shells | |

| with shot cup/ sabot | 10-60 bar |

| Full-Bore-Slugs | 30-80 bar |

- Bullet resistance

The Bullet resistance (BR) is a value that is usually determined and provided only by the bullet manufacturer. It is recommended to change the value only if you use a special bullet construction or material and know its value, or if you have determined the value experimentally! DO NOT use this function for regular standard jacketed bullets!

The input value “bullet resistance / friction”, which is independent of the barrel length, changes the resistance the bullet has against the combustion pressure as it moves through a barrel. Set this value to ZERO to use the default value. The default value is part of the energy losses considered in the simulation core and depends on the bullet length and the effective cross section.

Since the input value “bullet resistance / friction” is relative to the default value, you can also enter a negative value to reduce the resistance. A warning message appears in the simulation output if you fall below physical limits.

- Construction / Material

The Universal Bullet Classification Scheme UBCS-Code (follow link for more information) is a scheme to classify bullets by purpose, geometry, external and internal features. It is used to simplify the task of finding alternative bullet types by application and/or intended purpose. This value has no influence on the simulation.